More options

X-Y Motion

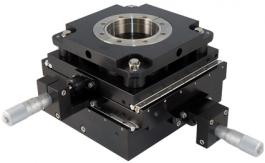

X-Y translator drawing

X-Y translator

Micrometers

| Size | X-Y Travel (+/- mm) | Clear ID | A (mm) | B (mm) | C (mm) | H (mm) | P/number |

|---|---|---|---|---|---|---|---|

| CF40 | 12,5 mm | 38 mm | 203 | 130 | 114 | 5-XY-1000 | |

| CF63 | 12,5 mm | 73 mm | 227 | 183 | 316 | 117 | 5-XY-1250 |

| CF63 | 25 mm | 73 mm | 297 | 208 | 401 | 143 | 5-XY-1251 |

| CF100 | 12,5 mm | 100 mm | 253 | 242 | 375 | 127 | 5-XY-2501 |

| CF100 | 25 mm | 100 mm | 253 | 242 | 375 | 155 | 5-XY-2502 |

| Material: | |

|---|---|

| Body: | Stainless steel - anodized Al |

| Bellow: | AM-350 edge welded |

| Bearings: | Stainless steel |

| Vacuum: | 10-11 mbar |

| Temperature: | -20°C to 210°C |

DC stepper motion actuated available upon request, please contact our sales office.

DC stepper motion actuated available upon request, please contact our sales office.

Resolution:

- with small micrometers (standards): >10μm

- with large micrometers: >2.5μm

Repeatability:

- with small micrometers (standards): >5μm

- with large micrometers: >1.25μm

The series of XY translators combine extremely high rigidity, a large working bore and affordable cost. They are available in both ± 25 mm and ± 12.5 mm travel, circular pattern, with both manual and stepper motorized versions. In fact, conversion from micrometers to stepper motors can be done in 15 minutes at the user's site. Both the translators have features not found on translators available elsewhere, such as tilt adjustment on the top flange, standard.

One distinct advantage of the translators is the cost savings when long Z Axis strokes are required. Since only the bellows in the XY portion needs to be larger than the probe, the user can extend the Z Axis stroke using a smaller diameter (less costly) bellows that just clears the probe running through it. Simply select the model available that best suits your needs. For horizontal mounting, i.e., with the flange faces vertical, dual constant force counterbalance springs are available that compensate for gravitational loads. If required, this feature can be added in the field, after the user accurately determines the weight of the devices to be mounted.

To make your selection, add the total travel required in either the X or Y axis to the maximum diameter of the device that will pass through the translator. This sum determines the minimum bellows inside diameter (ID). Next, select the bottom flange that best mates to your chamber or other equipment. While the most common size is 150mm OD, either tapped or non-tapped flange sizes of 114 mm, 150 mm, 200 mm and larger are available.

To make your selection, add the total travel required in either the X or Y axis to the maximum diameter of the device that will pass through the translator. This sum determines the minimum bellows inside diameter (ID). Next, select the bottom flange that best mates to your chamber or other equipment. While the most common size is 150mm OD, either tapped or non-tapped flange sizes of 114 mm, 150 mm, 200 mm and larger are available. Now you are ready to select a Z axis translator that best mates to the device to be manipulated, to complete your XYZ sample manipulation needs