More options

Subminiature C

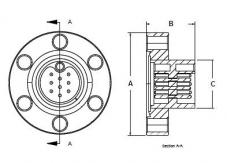

Fig.1 CF flange style

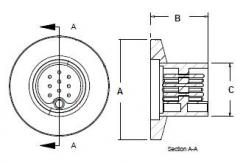

Fig.2 ISO-K flange style

Sub-c KIT

| N. pin | Flange | Amp | A | B | C | Part number |

|---|---|---|---|---|---|---|

| 9-KIT | CF16 | 5 | 34 | 16 | 15.7 | 1-MP-0065 |

| 9 | CF16 | 5 | 34 | 16 | 15.7 | 1-MP-0066 |

| 9 | CF40 | 5 | 70 | 16 | 15.7 | 1-MP-0063 |

| 2x9 | CF40 | 5 | 70 | 16 | 15.7 | 1-MP-0067 |

| 9-KIT | KF16 | 5 | 30 | 17.3 | 15.9 | 1-MP-0068 |

| 9 | KF16 | 5 | 30 | 17.3 | 15.9 | 1-MP-0069 |

| 9 | KF40 | 5 | 55 | 14.7 | 15.9 | 1-MP-5051 |

| 2x9 | KF40 | 5 | 55 | 14.7 | 15.9 | 1-MP-5050 |

| Kit includes: | ||||||

| - CF16 Feedthrough - | ||||||

| - 2400mm air side cable with connector - | ||||||

| - 500mm UHV kapton insulated cable with PEEK connector - |

| Voltage: | 500V DC |

|---|---|

| Current | 5A max at 20°C (3A per pin all pins loaded) |

| Material | |

| Flanges | 304 stainless steel |

| Shell | Stainless steel |

| Pins | Ni-Fe alloy, gold plated |

| Seal/Insulation | Glass/Ceramic |

| Vacuum range UHV/HV | 1x10-10 / 1x10-8 mbar |

| Temperature range | |

| CF mounted FT | 250°C |

| KF mounted FT | 150°C |

| Air side connector | 125°C |

| Thermal gradient | 25°C/min |

Custom configurations available upon request. Please contact our sales office.

Custom configurations available upon request. Please contact our sales office.

Multipin feedthrougs Subminiature-C multi-pin hermetic feedthroughs are designed for applications where space is limited or where Subminiature-D connections will not fit. The compact design allows installation into CF16 metal seal and KF16 elastomer seal flanges.

Multipin feedthrougs Subminiature-C multi-pin hermetic feedthroughs are designed for applications where space is limited or where Subminiature-D connections will not fit. The compact design allows installation into CF16 metal seal and KF16 elastomer seal flanges.

Nine gold plated pins are in a straight through pin-to-pin design and are hermetically sealed and electrically insulated in a stainless steel shell using the latest in glass-ceramic bonding technology.

Nine gold plated pins are in a straight through pin-to-pin design and are hermetically sealed and electrically insulated in a stainless steel shell using the latest in glass-ceramic bonding technology.

Air and vacuum side connectors are fitted with captured stainless steel socket head screws that provide a means of securely locking them to their mating feedthroughs. On the vacuum side, Kapton insulated cable assemblies fitted with PEEK connectors are available to meet the demands of ultrahigh vacuum environments. In-vacuum connector screws are vented where required and the feedthrough's screw-boss functions as a locating key.

Air and vacuum side connectors are fitted with captured stainless steel socket head screws that provide a means of securely locking them to their mating feedthroughs. On the vacuum side, Kapton insulated cable assemblies fitted with PEEK connectors are available to meet the demands of ultrahigh vacuum environments. In-vacuum connector screws are vented where required and the feedthrough's screw-boss functions as a locating key.

Air to vacuum pin position is identified with a permanent surface mark, which clearly locates pin assignments.

Air to vacuum pin position is identified with a permanent surface mark, which clearly locates pin assignments.