More options

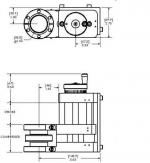

CF40 compact Z translator

Z column

Single axis

| Size | Travel | ID bore | Compressed length | Part number |

|---|---|---|---|---|

| CF40 | 50 | 38 mm | 66 mm | 5-MT-0210 |

| CF40 | 75 | 38 mm | 70 mm | 5-MT-0211 |

| CF40 | 100 | 38 mm | 75 mm | 5-MT-0212 |

| CF40 | 150 | 38 mm | 87 mm | 5-MT-0213 |

| CF40 | 200 | 38 mm | 100 mm | 5-MT-0214 |

| CF40 | 250 | 38 mm | 112 mm | 5-MT-0215 |

| CF40 | 300 | 38 mm | 125 mm | 5-MT-0216 |

| CF40 | 400 | 38 mm | 150 mm | 5-MT-0217 |

| CF40 | 500 | 38 mm | 175 mm | 5-MT-0218 |

| CF40 | 600 | 38 mm | 200 mm | 5-MT-0219 |

| Material: | |

|---|---|

| Body: | Stainless steel - anodized Al |

| Bellow: | AM-350 edge welded |

| Vacuum: | 10-11 mbar |

| Temperature: | 150°C (210°C intermittent) |

DC stepper motion actuated available upon request, please contact our sales office.

DC stepper motion actuated available upon request, please contact our sales office.

The newest member of the CF40 translator family, has the cantilever brackets bolted to the side of the flange. The advantage here is that the cantilever brackets leave 75% of the circumference of the flange unobstructed. This allows the translator to mount in very close quarters without interfering with other, nearby flanges.

Despite its modest price, the manipulator will provide years of trouble-free service, especially if the simple maintenance is performed.

All our manipulator lead screws use ball bearings. The lead screws are dry lubricated with baked-on molybdenum disulfide and the bearings are lubricated with molybdenum disulfide grease for low friction and long life. All parts are field replaceable, including the bellows. All translators are also available with long strokes, motor drives, linear encoders, tapped flanges and special heights.

Maintenance Instructions:

The Z stage needs only minimal maintenance. The linear bearings are self-lubricating and the guiderods and jacking screw need only be kept clean and free from dirt, dust and debris. The jacking screw and bearings do, however, need periodic lubrication.

As delivered, the screws are coated with baked-on molybdenum disulfide. This coating will degrade over time, due to moisture in the atmosphere. After each bake out, lightly relubricate the screws with the (provided) silicone-based molybdenum disulfide grease. Be especially careful not to use a hydrocarbon grease such as Felpro C100TM unless you periodically clean the oxidized residue from all load-bearing surfaces. The normal bakeout temperature is 150oC but higher temperatures can be used, if needed. For bakeouts between 150oC and 210oC, increase the frequency and thoroughness of lubrication.

To thoroughly re-lubricate the bearings while the translator is under vacuum,

-

First move the translator to its fully extended position.

Place a spacer between the traveler and lower bracket. (Wood or metal work well.) - Remove the bearing retainer flange on the lower bracket.

- Turn the knob counterclockwise to extract the bearings from the lower bracket.

- Work the factory-supplied grease into the bearing. Remember: a little goes a long way!

-

Replace the bearing, retainer and screws.

Remove the spacer. - Do science.