More options

Two stage differentially pumped rotary platform

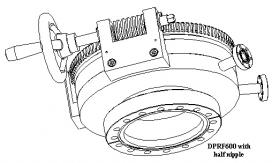

DPRP on CF40 flange

DPRP on CF63 flange with stepper motor

Half nipple

| Size | Clear ID | A (mm) | B (mm) | C (mm) | Axial load capacity (Kg) | Type | P/number |

|---|---|---|---|---|---|---|---|

| CF40 | 38 mm | 114 | 50 | 28 | 68 | Rotary platform | 5-RP-0275 |

| CF63 | 73 mm | 150 | 48 | 37 | 122 | Rotary platform | 5-RP-0450 |

| CF100 | 102 mm | 216 | 63 | 37 | 204 | Rotary platform | 5-RP-0600 |

| CF160 | 153 mm | 267 | 66 | 41 | 270 | Rotary platform | 5-RP-0800 |

| CF200 | 204 mm | 325 | 70 | 41 | 545 | Rotary platform | 5-RP-1000 |

| CF40 | 38 mm | Half nipple | 5-RP-0275-HN | ||||

| CF63 | 73 mm | Half nipple | 5-RP-0450-HN | ||||

| CF100 | 102 mm | Half nipple | 5-RP-0600-HN | ||||

| CF160 | 153 mm | Half nipple | 5-RP-0800-HN | ||||

| CF200 | 204 mm | Half nipple | 5-RP-1000-HN |

| Material: | |

|---|---|

| Body: | Stainless steel - anodized Al |

| Seals | Elastomer |

| Worm & gear: | St. St. and bearing bronze |

| Vacuum: | 10-11 mbar |

| Temperature: | -20°C to 210°C |

For stepper or DC motors, please contact our sales office

For stepper or DC motors, please contact our sales office

Differentially pumped rotary platforms provide 360° of continuous rotary freedom through the wall of any vacuum system. The DPRP-series have two stages of differential pumping isolated by fluorocarbon seals on precision sealing surfaces. The rotating stage runs on high strength ball bearings. This allows the unit to be successfully used with manipulators and other precision positioning devices. All DPRP-series platforms come with a fine adjust worm drive and 0.1° vernier scale for easier and more accurate angle adjustment.

Performance:

The excellent performance of our rotary platform coupled with a simple, low maintenance design gives maximum value. The fine adjust worm has bearings at both ends, thereby eliminating deflection and inaccuracies. Worm gear backlash is reduced to <0.05 degrees. The bolt holes on both flanges are tapped full depth for use with standard length flange hardware. This means no need to shorten standard fasteners. Fluorocarbon seals are double-differentially pumped to provide base pressures in the 10-11Torr range and will withstand bakeouts up to 210°C.

On CF63 rotary platforms and larger, there are multiple mounting locations for the index plate and fine adjust drive. This means the fine adjust drive can be positioned almost anywhere relative to the pump-out ports, ensuring compatibility with any installation.

The integral half-nipple option, for mounting to an existing tapped flange, saves space, hardware, time and money (see drawing).

The DC motor option includes a variable speed drive controller and pendant switch. Stepper motor drives are also available.